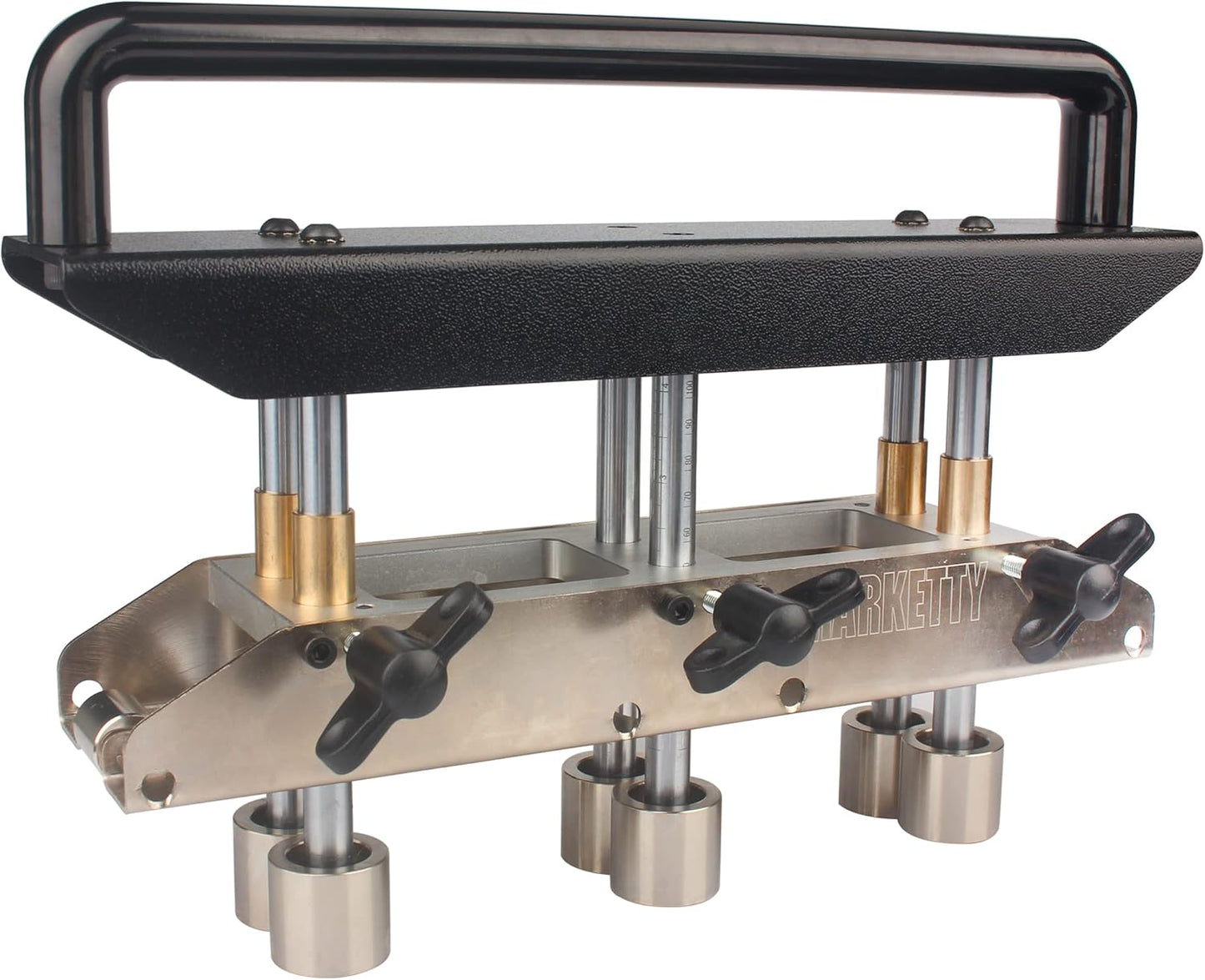

ER3 Three-Station Edge Roller Bender, Large Radius Sheet Metal Bead Roller Bender/Brake, 0-90° Bending Angle, Adjustable for Making 5/8" to 4" (16 to 102 MM) Bends in 29 to 22-Gauge Steel

ER3 Three-Station Edge Roller Bender, Large Radius Sheet Metal Bead Roller Bender/Brake, 0-90° Bending Angle, Adjustable for Making 5/8" to 4" (16 to 102 MM) Bends in 29 to 22-Gauge Steel

Low stock: 2 left

SKU:B0BNHYR7B8

Couldn't load pickup availability

Easy to Adjust - Sheet metal brake for clean, crisp bends in metal roofing materials(e.g. steel/aluminium/Copper etc.), Making 5/8" to 4" (16 to 102 mm) bends in 29 to 22-gauge (0.36 to 0.76 mm) steel. The ER3 is capable of bending straight bends of an infinite length up to 90 degrees. | Create Curved Bends - Exclusive 3-station bead roller design produces a uniform bend, outer rollers may travel off material out to the very ends of a straight panel length, assuring a uniform bend along the entire length of the material. The centre roll station of the sheet metal tools can be adjusted independently to create curved bends and the outer roll station retracted and locked to allow bending in curves. | Accurate Depth Gauge - There is a precision English/Metric depth gauge on one shaft leg of the center roller station of the ER3 Metal Edge Roller. When locked in place at the desired setting, you can accurately align the depth of all roller stations,then get the accurate size of bends you need. | Quality Construction - With upgraded aluminum alloy handle, our sheet metal Bender offer you a comfortable grip. Jobs that require moving will become hassle-free, ands comfortable adjustment knob holds the depth setting securely in place. Made from high-quality nylon and tough metal. which ensure long service life for this bead roller. | Tips from Marketty - Make sure you have a straight cutting edge on the material you are bending and do not bend the material quickly to prevent rippling of the material. Apply light pressure to the metal bending tool and make several bends, each time bending the material upwards by approximately 10-20 degrees. For a 90 degree bend you should plan to have the tool run back and forth at least 5 to 8 times. Any question please feel free to contact us, we will always be here ready for help.

Share